If you’re looking for the best industrial-grade protocol analyzers, I recommend considering options like Waveshare’s CAN/CAN FD Data Analyzers, which feature high-speed, fully isolated interfaces for reliable monitoring in tough environments. Devices like Keenso’s USB to CAN FD converters and other rugged analyzers offer support for multiple protocols, high data transfer rates, and advanced safety features. Keep exploring further to discover which model best suits your specific needs and guarantees dependable network analysis.

Key Takeaways

- Compatibility with multiple protocols like CAN 2.0A/B, CAN FD, and proprietary standards ensures versatile industrial network analysis.

- Robust, fully isolated interfaces (USB, CAN) provide electrical safety, ground loop prevention, and noise immunity in harsh environments.

- High-speed data transfer capabilities and FPS up to 20,000 enable real-time monitoring and efficient troubleshooting.

- Durable, rugged design with industrial-grade materials guarantees reliability in dust, moisture, and mechanical shock-prone settings.

- Extensive software support, including drivers, SDKs, and tutorials, facilitates easy deployment and integration across various platforms.

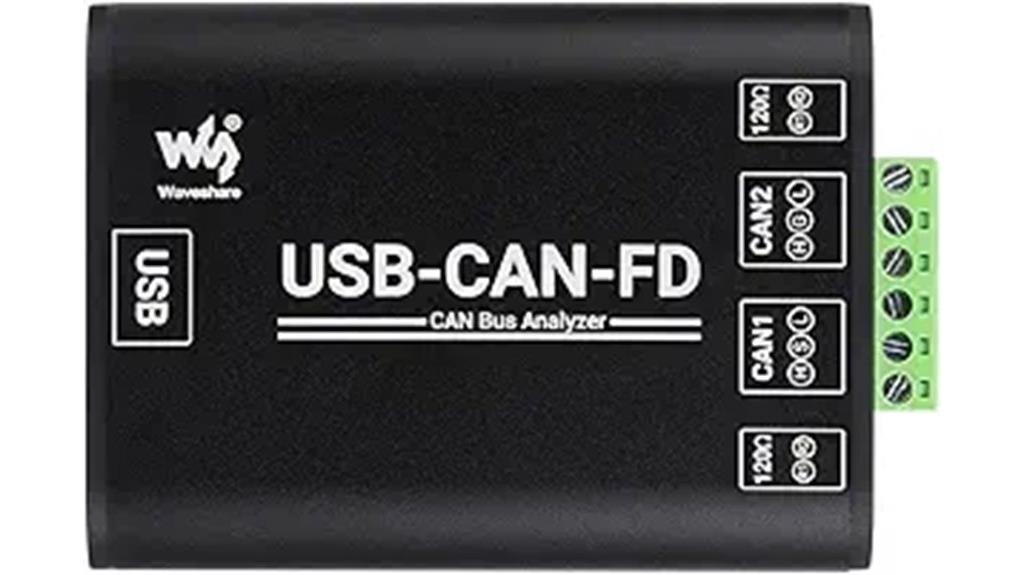

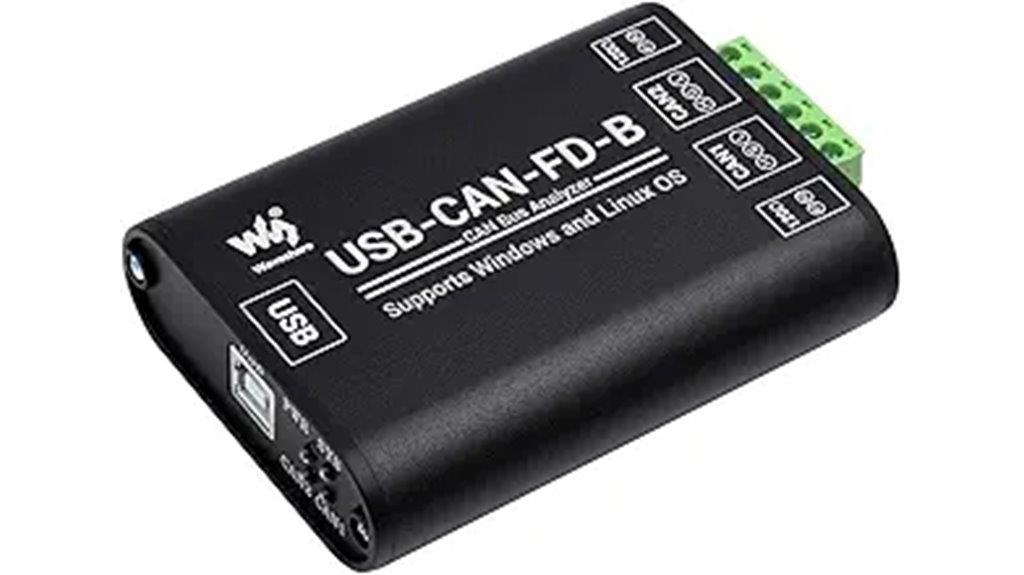

If you’re working in industrial environments that demand reliable and robust communication analysis, the Waveshare Industrial CAN/CAN FD Bus Data Analyzer is an excellent choice. I’ve used this high-performance USB adapter to connect and monitor CAN/CAN FD bus networks easily. It features dual independent interfaces with electrical isolation and protection circuits, ensuring stable operation even in harsh conditions. The device supports Windows systems and comes with drivers, software, and development tools, making integration straightforward. Whether for debugging, data collection, or secondary development, its compact design and user-friendly interface make it ideal for industrial automation, power communication, and intelligent control applications.

Best For: professionals and engineers working in industrial automation, power communication, and intelligent control systems requiring reliable CAN/CAN FD bus data analysis and debugging.

Pros:

- High-performance dual independent CAN FD interfaces with electrical isolation for enhanced reliability

- Supports multiple Windows platforms with comprehensive drivers, software, and development tools

- Compact, user-friendly design suitable for various industrial environments and applications

Cons:

- Limited to Windows operating systems, not compatible with macOS or Linux without additional software

- May require technical knowledge for setup and integration into complex systems

- Cost could be higher compared to basic CAN adapters without advanced features

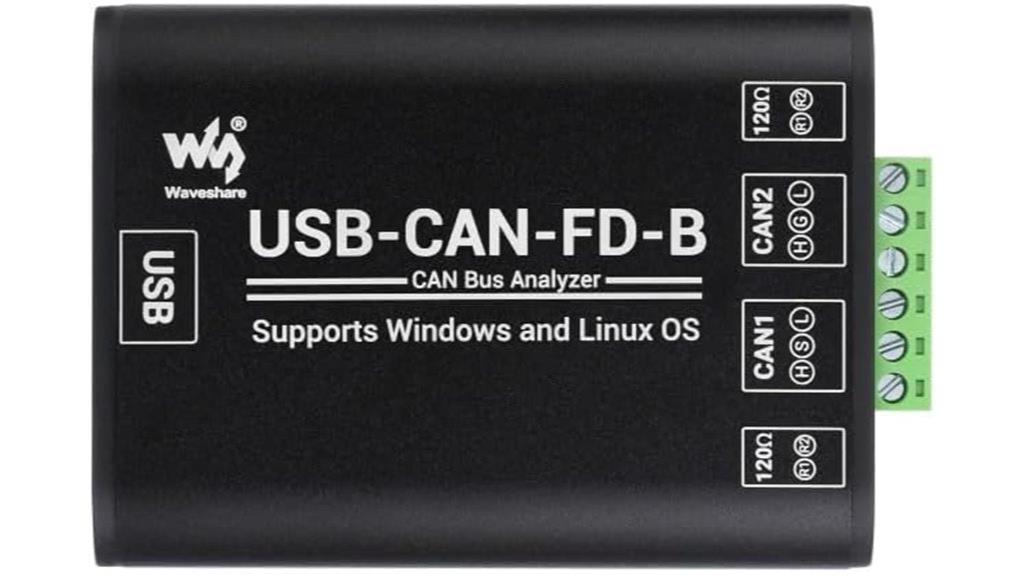

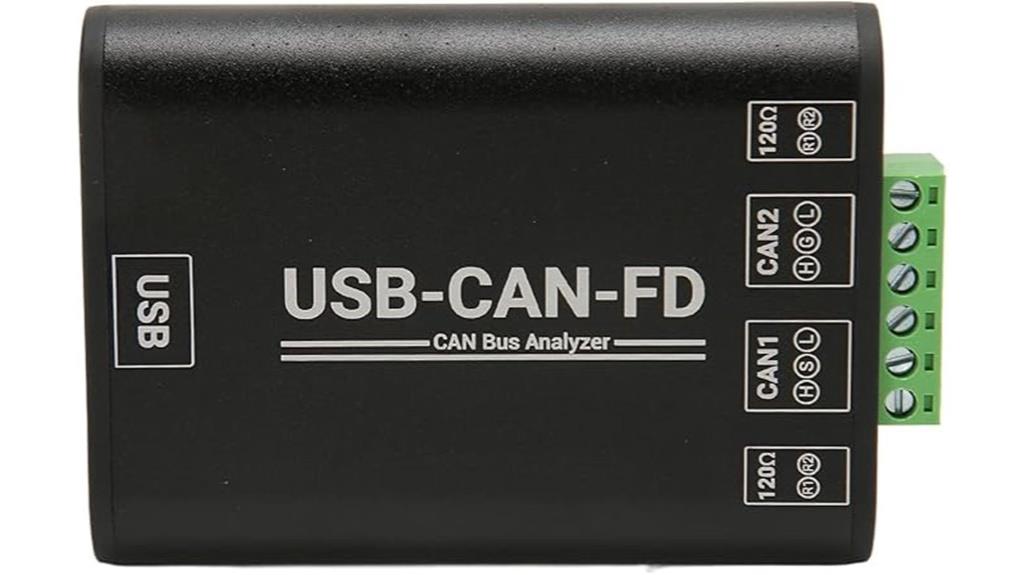

The Waveshare Industrial CAN/CAN FD Data Analyzer and Adapter is ideal for professionals who need reliable, real-time analysis of CAN bus networks in demanding industrial environments. It features dual independent CAN FD interfaces with electrical isolation and protection circuits, ensuring stable operation. The device connects via USB to PCs or control systems, supporting functions like transceiver control, data collection, and network monitoring. Compatible with Windows and Linux, it includes drivers, analysis software, and development resources. Its compact design makes it easy to operate in tight or challenging settings, making it a versatile choice for industrial, power communication, and automation applications.

Best For: professionals and engineers in industrial, automation, and power communication sectors seeking reliable, real-time CAN bus network analysis and monitoring.

Pros:

- Dual independent CAN FD interfaces with electrical isolation for enhanced stability and safety

- Compatible with Windows and Linux, supporting diverse software and development needs

- Compact and easy-to-operate design suitable for challenging industrial environments

Cons:

- May require technical expertise for setup and integration

- Limited to CAN/CAN FD network analysis, not suitable for other communication protocols

- Potential need for additional accessories or software for advanced features

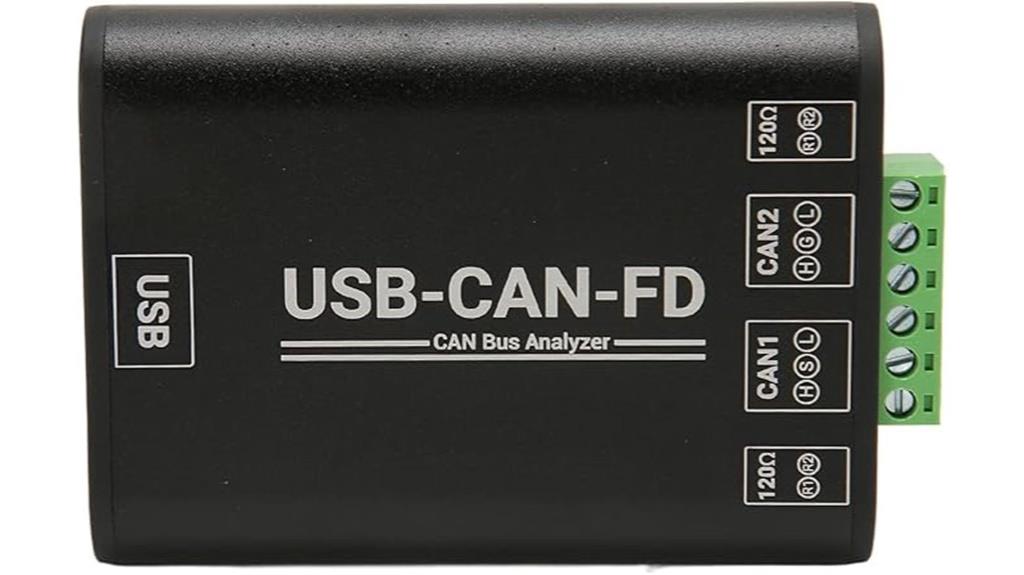

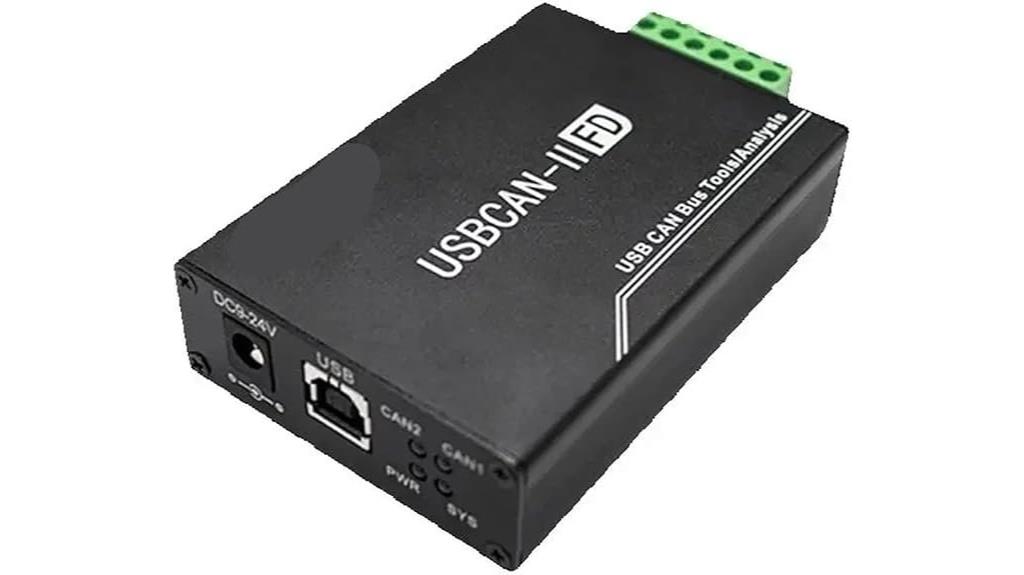

Industrial CAN/CAN FD Data Analyzer and USB Adapter

Designed for demanding industrial environments, the Industrial CAN/CAN FD Data Analyzer and USB Adapter offers high-speed, bi-directional communication across multiple CAN networks. It features onboard USB 2.0 and two independent CAN/CAN FD interfaces, supporting simultaneous operation without interference. The device is compatible with CAN 2.0A, CAN 2.0B, ISO11898-1, and CAN FD Protocol V.1.0, handling both standard and extended frames. Baud rates are adjustable from 100 Kbps to 5 Mbps, with automatic detection and manual configuration options. Built with reliable microcontroller technology, it guarantees stable, secure data exchange, making it ideal for complex industrial monitoring tasks.

Best For: industrial automation engineers and technicians requiring reliable, high-speed CAN/CAN FD data analysis and secure communication in demanding environments.

Pros:

- Supports multiple CAN protocols and both standard and extended frames for versatile network compatibility

- Automatic and manual baud rate configuration for flexible setup and precise control

- Fully isolated interfaces (USB, CAN1, CAN2) enhance security and stability in harsh conditions

Cons:

- May require technical expertise for optimal configuration and setup

- Limited to USB 2.0 interface, which might restrict data transfer speeds in extremely high-throughput scenarios

- The device’s complexity could be overkill for simple or small-scale applications

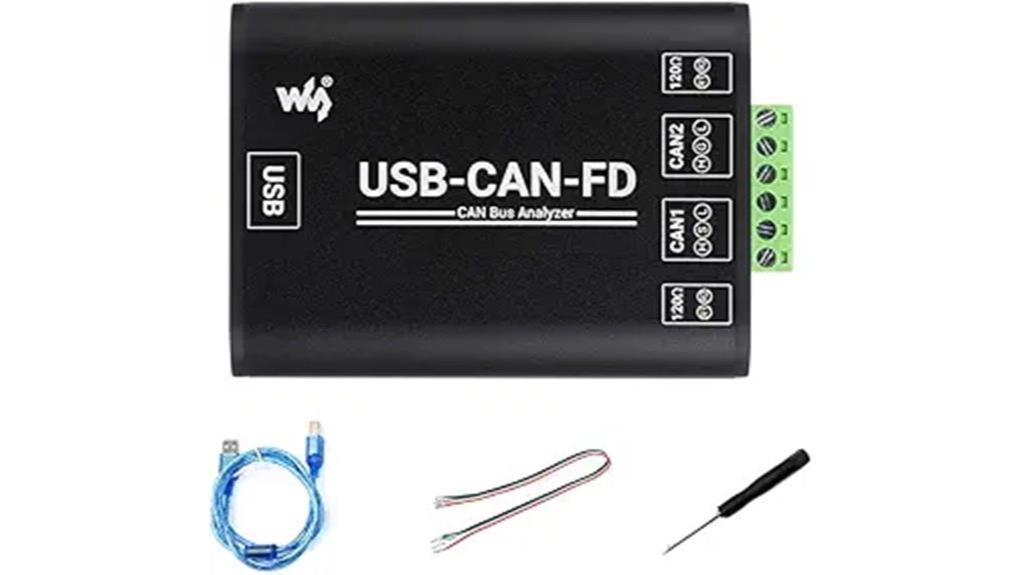

Industrial CAN/CAN FD Bus Data Analyzer, USB Adapter

For professionals working with industrial communication networks, the Industrial CAN/CAN FD Bus Data Analyzer USB Adapter offers a powerful and reliable solution. This industrial-grade device supports Windows and Linux, including Raspberry Pi OS and virtual machines, making it versatile for various setups. It features dual CAN FD interfaces with electrical isolation for enhanced protection and stability. Supporting baud rates from 100Kbps to 5Mbps, it enables flexible network analysis and troubleshooting. With high-speed USB 2.0, multiple simultaneous connections, and all-encompassing software support, it’s ideal for learning, debugging, and industrial integration across power, control, and communication systems.

Best For: professionals and engineers who need a reliable, industrial-grade solution for CAN/CAN FD network analysis, debugging, and integration across power, industrial control, and communication systems.

Pros:

- Supports dual independent CAN FD interfaces with electrical isolation for enhanced safety and stability.

- Compatible with Windows, Linux, Raspberry Pi OS, and virtual machines, offering versatile deployment options.

- Capable of handling baud rates from 100Kbps to 5Mbps with auto-detection and configuration support for flexible network analysis.

Cons:

- May require technical expertise for setup and secondary development.

- Limited to industrial and communication environments; not designed for consumer-grade applications.

- First available in October 2024, which could affect immediate procurement or integration plans.

Keenso CAN FD Protocol Data Analyzer USB to CAN FD Convertor

If you need a reliable solution for high-speed data analysis across various CAN protocols, the Keenso CAN FD Protocol Data Analyzer USB to CAN FD Convertor stands out. It supports multiple protocols, including CAN2.0A/B and CAN FD, offering versatile application options. With a transfer capability of up to 20,000 frames per second per interface, it guarantees efficient, real-time data flow. The device features indicator lights for power, system status, and channel activity, giving instant operational feedback. Built from durable aluminum alloy, it provides stable, long-lasting performance suitable for demanding industrial environments, making it an excellent choice for extensive network monitoring.

Best For: professionals and industrial technicians needing high-speed, reliable CAN protocol data analysis across diverse network systems.

Pros:

- Supports multiple protocols including CAN2.0A/B and CAN FD for versatile application

- High data transfer rate of up to 20,000 frames per second per interface for efficient real-time analysis

- Durable construction with aluminum alloy build ensures long-lasting performance in demanding environments

Cons:

- May require technical expertise to optimize setup and operation

- Limited to USB connectivity, which could restrict mobility in some scenarios

- Indicator lights provide basic status updates but lack detailed diagnostic information

Industrial CAN/CAN FD Bus Protocol Data Analyzer and USB to CAN FD Adapter

The Industrial CAN/CAN FD Bus Protocol Data Analyzer and USB to CAN FD Adapter stands out as an essential tool for engineers and technicians who need reliable, real-time monitoring and analysis of CAN bus networks. It connects seamlessly to PCs via USB, supporting Windows XP through 11, and includes drivers, software, and tutorials for easy setup. Its compact, user-friendly design makes it ideal for debugging, learning, and development. With two independent CAN/CAN FD interfaces, it supports standard and extended frames, ensuring broad compatibility. This device is perfect for industrial automation, power communication, and control systems, offering efficient data collection, monitoring, and system integration capabilities.

Best For: engineers and technicians in industrial automation, power communication, and control systems seeking reliable, real-time CAN bus data analysis and monitoring solutions.

Pros:

- Supports a wide range of protocols including CAN 2.0A/B and CAN FD, ensuring broad compatibility.

- Compact, user-friendly design ideal for learning, debugging, and development tasks.

- Dual independent CAN/CAN FD interfaces facilitate simultaneous data transmission without interference.

Cons:

- Requires connection to a Windows PC, limiting use with other operating systems.

- May involve a learning curve for users unfamiliar with CAN bus systems and protocol analysis.

- Hardware and software updates might be necessary for compatibility with future standards or advanced features.

Industrial CAN/CAN FD Bus Data Analyzer and Interface Card

When precision and reliability are critical in industrial communication systems, the Industrial CAN/CAN FD Bus Data Analyzer and Interface Card stands out as an ideal solution. It features dual independent CAN FD interfaces with electrical isolation and protection circuits, ensuring robust performance. Its compact design makes it easy to deploy for learning, debugging, or industrial integration. I’ve used it to monitor, analyze, and control CAN bus networks in diverse applications like automation and power communication. Supported by extensive software, drivers, and tutorials, it simplifies development and troubleshooting. This device delivers reliable, real-time data analysis essential for maintaining industrial network integrity.

Best For: industrial automation professionals, engineers, and researchers needing reliable real-time CAN/CAN FD data analysis and communication solutions.

Pros:

- Dual independent CAN FD interfaces with electrical isolation and protection circuits for enhanced reliability.

- Compact and easy-to-deploy design suitable for learning, debugging, and industrial integration.

- Extensive software support, including drivers, tools, tutorials, and development examples for streamlined integration and customization.

Cons:

- May require technical expertise to fully utilize advanced features and software tools.

- Compatibility may depend on specific operating systems and hardware setups.

- Cost could be higher compared to basic CAN interface devices due to advanced features and industrial-grade design.

Industrial USB to Can FD Adapter for Can/Can FD Bus Communication

For professionals working with industrial CAN and CAN FD networks, the Industrial USB to CAN FD Adapter stands out due to its dual independent interfaces and galvanic isolation, ensuring reliable and noise-resistant communication. Its robust design includes multiple circuits and an aluminum alloy construction, making it durable for long-term industrial use. The adapter connects easily via USB to PCs or control hosts, supporting data sending, receiving, and network monitoring. Compatible with various operating systems and equipped with drivers, tools, and tutorials, it simplifies integration and customization. Whether for debugging, data logging, or real-time analysis, this adapter is a versatile solution for industrial CAN/CAN FD applications.

Best For: professionals and engineers working with industrial CAN and CAN FD networks who need reliable, noise-resistant communication, data monitoring, and debugging solutions.

Pros:

- Dual independent CAN FD interfaces with galvanic isolation for enhanced reliability

- Durable aluminum alloy construction suitable for long-term industrial use

- Compatible with multiple operating systems, supporting easy integration and customization

Cons:

- May require technical expertise for setup and configuration

- Potentially higher cost compared to simpler USB-to-CAN adapters

- Limited to industrial environments, not ideal for casual or non-industrial applications

Industrial-Grade CANbus Data Analyzer (USB to CAN FD Interface)

An industrial-grade CANbus data analyzer with a USB to CAN FD interface is ideal for engineers and technicians who need reliable, high-speed data monitoring in demanding environments. It supports baud rates from 100Kbps to 5Mbps and features dual CAN FD interfaces, allowing for simultaneous data analysis. Its programmable baud rate and flexible logic circuits enable customization for various communication standards, including CAN2.0A and B, compliant with ISO11898-1. The device’s 2500V isolation guarantees electrical safety and noise immunity, making it perfect for industrial settings. Its compact size and rugged design simplify deployment, providing a dependable solution for high-performance CAN bus diagnostics.

Best For: engineers and technicians needing reliable, high-speed CAN bus data analysis in industrial environments.

Pros:

- Supports a wide range of baud rates from 100Kbps to 5Mbps, offering high flexibility.

- Dual CAN FD interfaces enable simultaneous data monitoring and analysis.

- 2500V isolation ensures electrical safety and noise immunity in demanding settings.

Cons:

- Compact design may be challenging to handle for users with larger hands or limited dexterity.

- Requires a computer with compatible software; standalone operation is not available.

- No built-in batteries, so constant power connection is necessary for operation.

Industrial-Grade CANbus Data Analyzer and Interface Converter

The Industrial-Grade CANbus Data Analyzer and Interface Converter is ideal for professionals who need reliable, high-speed data analysis in demanding industrial environments. It supports baud rates from 100 Kbps up to 5 Mbps and features an USB to CAN FD interface converter. Equipped with programmable logic circuits, it handles CAN2.0A and B protocols, compliant with ISO11898-1 standards. Its integrated 2-way CANFD interface operates between 40 Kbps and 1 Mbps, ensuring flexible communication. With a 2500V isolation rating, it guarantees safety and reliability during operation. Compact and lightweight, it’s perfect for on-the-go use, offering customizable and precise data analysis for industrial applications.

Best For: professionals in industrial environments requiring high-speed, reliable CANbus data analysis and communication with customizable and safety features.

Pros:

- Supports a wide baud rate range from 100 Kbps to 5 Mbps for versatile data analysis.

- Equipped with programmable logic circuits for customizable operation.

- Certified with 2500V isolation for enhanced safety and reliability during use.

Cons:

- Price may be higher compared to less advanced CANbus analyzers.

- Limited information on software compatibility and user interface.

- Requires technical expertise for optimal configuration and operation.

Industrial Grade Beidou GPS-IMU Sensor (WTGAHRS3-TTL)

Industrial-grade environments demand highly reliable navigation solutions, and the WitMotion WTGAHRS3-TTL meets this need with its 6-axis inertial measurement capabilities. It combines GPS-IMU, accelerometers, gyroscopes, and angle sensors to deliver precise orientation and movement data. With static accuracy of 0.05° and dynamic accuracy of 0.1°, it provides extensive navigation details, including latitude, longitude, altitude, and ground speed. Equipped with high-performance sensors and advanced filtering algorithms, it guarantees stable, low-noise measurements even in challenging conditions. Its robust design and reliable processing make it ideal for demanding industrial applications requiring consistent positioning and orientation data.

Best For: industrial professionals and engineers requiring highly accurate, reliable navigation solutions in challenging environments.

Pros:

- Combines GPS-IMU, accelerometers, gyroscopes, and angle sensors for comprehensive data.

- Static accuracy of 0.05° and dynamic accuracy of 0.1° ensures precise orientation measurements.

- Robust, durable design with advanced filtering algorithms guarantees stable, low-noise performance.

Cons:

- May require technical expertise for optimal setup and integration.

- Higher cost compared to consumer-grade alternatives.

- Limited to industrial-grade applications, not suitable for casual or recreational use.

3-Phase Power Meter with RS485 Protocol

If you’re looking for a reliable solution to monitor three-phase power systems accurately, a Phase Power Meter with RS485 protocol stands out. It offers Class 1 accuracy (±1%), measuring current up to 80A directly or higher with CTs, and supports voltages from 90V to 1000V using external PTs. Compatible with both 3-phase 4-wire and 3-wire systems, it’s versatile for industrial and commercial use. The device features a rotating LCD displaying 18 metrics, including kWh, voltage, current, and power factor. Its RS485 communication, supporting Modbus at 9600bps, enables seamless integration into remote monitoring systems.

Best For: industrial and commercial facility managers seeking accurate, reliable three-phase power monitoring with easy integration and robust design.

Pros:

- High measurement accuracy (Class 1, ±1%) ensures reliable energy data.

- Supports a wide voltage range (90V-1000V) with external PTs for versatility across different electrical environments.

- Seamless communication via RS485 with Modbus protocol facilitates remote monitoring and system integration.

Cons:

- External PTs required for measuring voltages above 500V, adding to installation complexity and cost.

- Limited to 80A direct measurement; higher currents necessitate additional CTs.

- Configuration adjustments require access to the front panel with a default password, which could pose security concerns if not changed.

Factors to Consider When Choosing Industrial‑Grade Protocol Analyzers

When selecting an industrial-grade protocol analyzer, I focus on compatibility with the protocols I need to monitor and the data transfer speeds required for my applications. I also consider features like electrical isolation to protect my equipment, along with reliable software support and rugged build quality. These factors guarantee I get a tool that’s effective, durable, and tailored to my operational needs.

Compatibility With Protocols

Choosing the right protocol analyzer hinges on ensuring it supports the specific communication protocols your system uses. I look for devices that handle protocols like CAN 2.0A/B, CAN FD, ISO11898-1, or any proprietary standards relevant to my network. It’s essential they support both standard and extended frame types, accommodating different configurations. I also verify that the analyzer can operate at the required baud rates, from low speeds like 40 Kbps to high speeds up to 5 Mbps. If monitoring multiple network segments, I prefer analyzers capable of supporting multiple protocols simultaneously. Additionally, I check for software features that offer robust protocol decoding and analysis, ensuring I can interpret traffic thoroughly. Compatibility with your specific protocols is crucial for accurate diagnostics and reliable monitoring.

Data Transfer Speed

The speed at which a protocol analyzer can transfer data directly impacts its effectiveness in managing high-volume industrial networks. Faster transfer rates, ranging from 100 Kbps to 5 Mbps, enable real-time analysis of large volumes of CAN or CAN FD frames, reducing latency. Many analyzers support auto-detection and manual settings, providing flexibility for different environments. High transfer speeds improve data logging, debugging, and troubleshooting efficiency, especially in demanding industrial settings. The maximum frames per second (FPS), such as 20,000 FPS, reflects the analyzer’s responsiveness and ability to capture high-frequency signals accurately. Choosing an analyzer with adequate transfer speed guarantees reliable data capture without loss, even during busy bus communication, ensuring consistent performance and reliable network monitoring.

Electrical Isolation Features

Electrical isolation is a critical feature to contemplate because it protects both the analyzer and connected devices from voltage surges, transients, and electrical faults. Fully isolated interfaces prevent ground loops, reducing noise and interference, especially in high-speed data environments. High isolation voltage ratings, such as 2500V or more, are essential for safely handling industrial voltage levels and avoiding damaging electrical faults. Isolation also enhances system stability by maintaining separate reference grounds for the analyzer and network, minimizing data corruption risks. Furthermore, isolators shield sensitive electronics from potentially damaging faults, boosting overall reliability in harsh industrial settings. Prioritizing robust electrical isolation ensures your protocol analyzer operates safely, preserves signal integrity, and maintains consistent performance in demanding industrial environments.

Software and Support

Selecting the right industrial-grade protocol analyzer hinges on robust software support that seamlessly integrates with your existing systems. I look for extensive drivers, analysis tools, and development kits compatible with my operating system to streamline setup and operation. Detailed tutorials, user manuals, and troubleshooting resources are essential for quick onboarding and effective use. I also prioritize manufacturers that offer ongoing technical support, software updates, and firmware upgrades to keep up with evolving protocols. Flexibility in connection methods, such as USB, Ethernet, or virtual machine compatibility, is vital for deployment in diverse environments. Additionally, features like real-time data monitoring, frame filtering, and data logging greatly enhance my analysis capabilities, ensuring reliable network monitoring and troubleshooting.

Build Durability

When choosing an industrial‑grade protocol analyzer, considering build durability is essential because these devices often operate in demanding environments. They are built with tough materials like aluminum alloys and reinforced plastics to withstand harsh conditions. Robust housings protect internal components from dust, moisture, and mechanical shocks, ensuring reliable performance over time. High-quality connectors and shielding help prevent signal interference and physical damage during frequent use or transportation. Additionally, extensive protection circuits, such as electrical isolation and overvoltage safeguards, extend the device’s lifespan in challenging industrial settings. Build durability is also demonstrated by compliance with industry standards and certifications, confirming the analyzer has undergone rigorous testing. Prioritizing durability ensures your analyzer can withstand the rigors of your environment and deliver consistent, long-term performance.

Ease of Integration

Ensuring easy integration of an industrial‑grade protocol analyzer is vital for seamless operation within existing systems. I look for devices that support standard communication interfaces like USB, Ethernet, or serial ports, making setup straightforward. Compatibility with common operating systems such as Windows, Linux, or RTOS is essential, allowing flexible deployment across various industrial environments. I also prioritize analyzers offering SDKs and APIs, which enable custom integration and automation tailored to my workflows. Configurable settings and automatic detection features help simplify setup, reducing time and potential errors. Additionally, I consider whether the device can connect with multiple devices simultaneously, supporting scalable monitoring across complex networks. This combination ensures smooth integration, minimizes disruptions, and enhances overall system efficiency.

Frequently Asked Questions

What Are the Key Differences Between CAN and CAN FD Protocol Analyzers?

CAN protocol analyzers focus on standard CAN networks, capturing basic message frames and error detection, while CAN FD analyzers handle faster data rates and larger payloads, offering enhanced performance. CAN FD tools also support more complex error handling and extended data bits, making them suitable for advanced industrial applications. I find CAN FD analyzers more versatile for modern, high-speed networks, whereas traditional CAN analyzers are sufficient for simpler, legacy systems.

How Does Environmental Durability Affect Analyzer Performance?

Think of an analyzer as a trusty ship steering stormy seas; environmental durability keeps it afloat. Harsh conditions like dust, moisture, and extreme temperatures can compromise its sensors and electronics, causing misreads or failure. A rugged design acts as armor, ensuring the analyzer maintains peak performance amidst chaos. When your equipment endures the environment, your network monitoring remains steadfast, accurate, and reliable, no matter what nature throws its way.

Can These Analyzers Integrate With Existing Industrial Network Systems?

Yes, these analyzers can integrate seamlessly with existing industrial network systems. I’ve found that most models support standard protocols like Ethernet/IP, Modbus, and PROFINET, making setup straightforward. They often come with flexible interfaces and software that allow easy integration into your current infrastructure. This compatibility helps guarantee reliable monitoring without disrupting your operations, giving you real-time insights and peace of mind.

What Maintenance Routines Are Recommended for Long-Term Reliability?

To guarantee long-term reliability, I recommend regularly updating the firmware and software of your protocol analyzer. I also perform periodic calibration and check the device’s physical connections for wear or damage. Cleaning the equipment to prevent dust buildup is essential, and I monitor the device’s performance to catch any anomalies early. Consistent backups of configuration settings help minimize downtime, keeping your network monitoring smooth and dependable over time.

Are There Specific Certifications Required for Industrial-Grade Protocol Analyzers?

Absolutely, there are specific certifications for industrial-grade protocol analyzers, and it’s worth doing your homework. Certifications like IEC 61508, ISO/IEC 17025, and UL safety standards guarantee these tools meet rigorous safety and performance benchmarks. Think of it as hitting two birds with one stone—ensuring reliability and compliance. Always check that your chosen device has the necessary certifications to keep your network monitoring trustworthy and up to standard.

Conclusion

Choosing the right industrial-grade protocol analyzer is like selecting a sturdy compass for a challenging journey. It guarantees you navigate complex networks with confidence and precision. By understanding your specific needs and considering reliable options, you’ll steer clear of pitfalls and keep your systems running smoothly. Remember, the right tool isn’t just equipment—it’s your trusted guide through the intricate maze of industrial communication. Stay prepared, and your network will always lead you home.